Chem Green en

CHEM GREEN

Chemical products with special applications in the processes of: Oil drilling and production and environment.

A200 Series: This series are acid replacements that are environmentally safe, non-toxic and non-hazardous. In addition, they have dissolution characteristics very similar to those of the hazardous acids they replace.

Applications include:

- Removal of scale in boilers, heat exchangers and pipelines

- Downhole acidification

- Coil tube applications and cleaning

8500: Tank bottom reliquefaction and hydrocarbon recovery product. It is designed to liquefy tank bottom sludge, separate water and allow solids to settle. The separated liquid hydrocarbons can be recovered and sold.

Simple, straightforward sales process and profit margins are significant, especially if you can market the recovered hydrocarbon.

Products 8000/1000/5000: Converts carboxylic and phenolic acids into powerful surfactants to reduce the interfacial tension of water-in-oil emulsions.

Petroleum contains varying amounts of organic acids (carboxylic acids and phenolic acids) that can react with alkaline materials to form soaps. These soaps reduce the interfacial tension between the oil and water. This reduction in interfacial tension allows residual oil solutions in a reservoir pore to move more easily.

Our products have the ability to convert several of these carboxylic acids and phenolic acids into surfactants to benefit oil recovery. Improve surfactant efficiency by removing hardness ions from reservoir brines, thereby reducing surfactant adsorption on rock surfaces. By binding or precipitating hardness ions, it causes greater favorable oil release from the reservoir by preventing oils from adhering to metals or clay and prevents surfactants from adsorbing to the formation.

Demulsifiers / Foaming agents / Surfactants:

All of these products are widely used in the market. Field or laboratory tests are required to determine the optimum product (or blend).

Investment in tanks and wellhead feed systems and the ability to fill small bulk tanks is required.

CG-A100 AND CG-A200

These are patent-pending formulations designed to replace conventional hydrochloric acid-based fracturing mixtures, including formulations containing corrosion inhibitors, iron dispersants, surfactants and other special additives. This product provides corrosion protection well above the conventional “non-corrosive” classification, even at elevated temperatures. In addition, CG-A200 achieves this performance without the use of reportable, hazardous product ingredients or volatile/hazardous decomposition products.

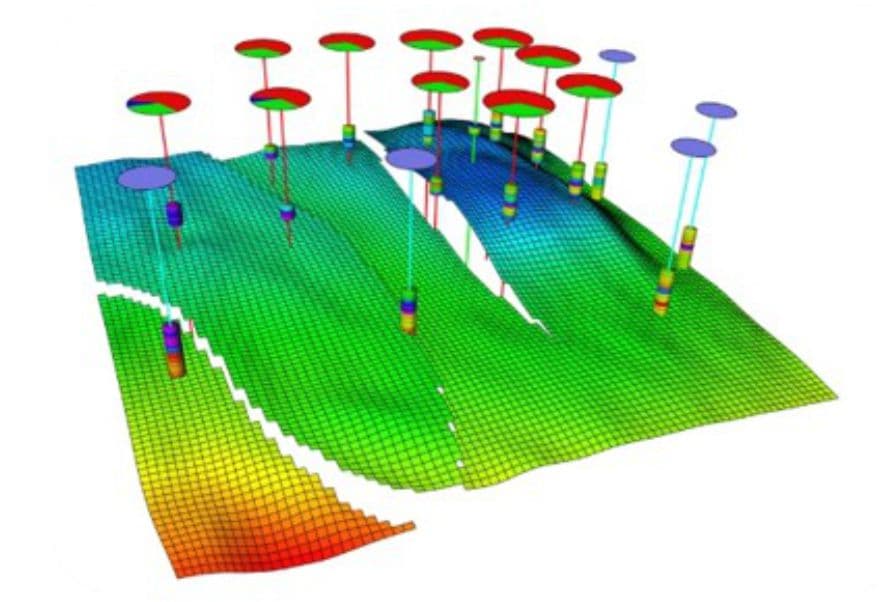

CG-1000 is an inorganic blend of sodium silicate and meta-silicate chemistries designed specifically for enhanced oil recovery (EOR). The formulation process results in unique types and ratios of functional silicates within the final product, with the final product containing an industry-leading silicon to sodium ratio in excess of a 4:1 ratio. As such, the resulting chemical compound has numerous field applications and uses. Finally, Eco-Treat is a stable, non-hazardous and environmentally friendly product.

CG-5000 is a polymer-surfactant-silicate based pH buffer solution designed specifically for Enhance Oil Recovery (EOR). It helps reduce interfacial tension and hardness ion concentrations, thereby increasing oil mobility. It is also designed to promote greater diffusion in the formation to release more oil. Ultimately, this leads to reduced concentration requirements for other polymers and surfactant additives that improve performance and profits. Finally, the products are water-based, non-toxic, non-flammable and environmentally safe (in RTU form).

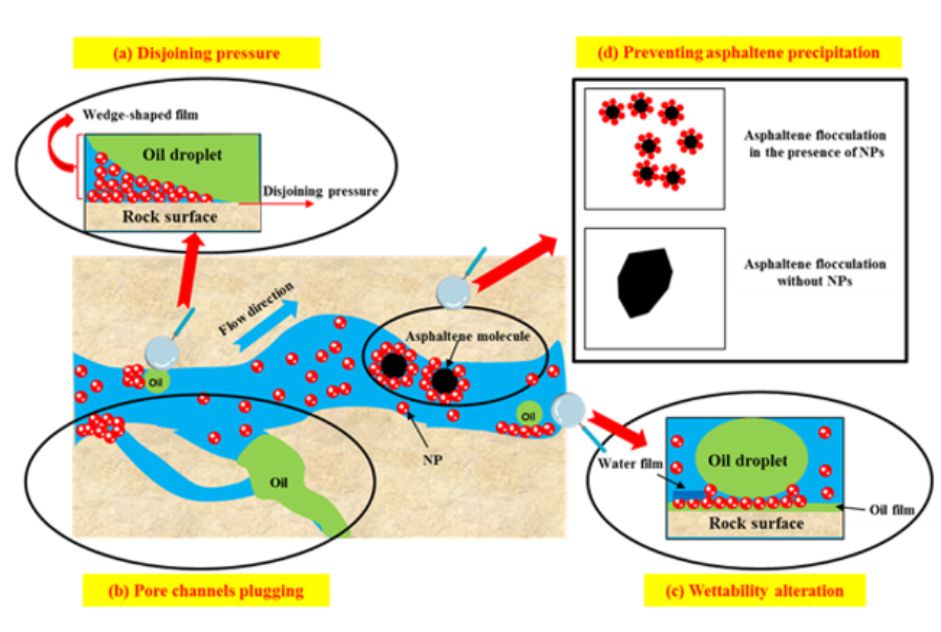

We offer a revolutionary product line that provides solutions to many hydrocarbon problems associated with kerosenes and asphaltenes. The products combine a unique blend of surfactant compounds with various surfactant stabilizing actives obtained from environmental wastes. The objective is to prevent the precipitation of asphaltenes and kerosenes in the formation of asphaltenes and kerosenes.