Zlpam en

ZL Group

It is a vertically integrated polyacrylamide manufacturer, a leader in polymer chemistry for oil and gas applications such as enhanced crude oil recovery, dual function friction reducers for hydraulic fracturing in slippery waters requiring superior friction reduction and proppant carrying capacity. ZL offers both liquid and dry friction reducers for a wide range of water qualities, including extreme water qualities exceeding 200,000 mg/l TDS.

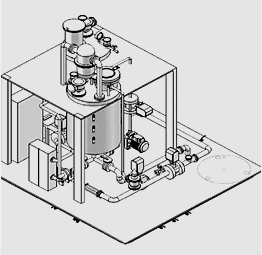

ZL Group also provides industry-leading equipment and services to optimize value for its customers when applying ZL’s new products downhole. Such services include laboratory services for polymer rheology, core analysis, engineering services (reservoir, production and facilities) for EOR design, implementation and optimization, as well as cost-effective compact polymer preparation units (CPDUs) for polymer hydration.

Choosing the right polymer chemistry for a specific reservoir and executing it at the right time of field development is extremely important to maximize oil recovery with polymer fluids. ZL was established in 1995, with a strong focus on polyacrylamide R&D and manufacturing for the enhanced oil recovery industry. We use our expertise, on-site experiences and reservoir understanding to help our clients design the most cost-effective program for their specific reservoir conditions. ZL works closely with exploration and production operators around the world in every phase of a polymer flood project, beginning in the laboratory with polymer chemistry design and evaluation, pilot testing and full field implementation.

Our proprietary manufacturing processes produce high molecular weight anionic polymers that have low shear susceptibility and increased tolerance in high temperature and brine environments. Our portfolio of friction reducers includes dry and liquid dual function friction reducers that operate in a wide range of water conditions.

ZL has been designing and manufacturing polymer dispersion units, also known as “dry on the fly” units, for the delivery of dry polymer to sites as well since 1995. ZL’s CPDU’s, compact Polymer Dispersion Units, are available in several versions to meet the specifications of different applications, including polymer flooding and hydraulic fracturing applications onshore and offshore.

Waterflooding is a secondary recovery process for displacing oil that has not been recovered by the primary recovery method. Waterflooding technology is often associated with a problem of unwanted water production resulting from unfavorable displacement caused by channeling water through highly permeable layers. The existence of high permeability zones (break-in zones) can lead to early water penetration and excessive water production, thus leaving a significant amount of bypassed oil in heterogeneous reservoirs. ZL’s conformance control technology consists of several different techniques to help our clients address their water-related problems.